HST - machines

HST - PT25

Complete automatic teabag packaging machine for non heatsealable double chamber filter bags with string, hard tag and knotted tea bags (low cost aluminum wire version also available). Each teabag is individually packed into a crimped paper envelope.

All machines are equipped with a Touch Panel KTP 700 and with a SPS S7 control and Software by Siemens!

Crimped paper outer envelope

machine type:

automatic teabag packaging machine

bag format:

double chamber filter bags with string and tag

bag type:

crimped paper outer envelope

Top Features

44 x 64 mm / 40 x 60 mm / 59 x 80 mm / 44 x 60 mm

up to 165 crimped outer paper envelopes per minute

L 255 cm / W 90 cm / H 195 cm

900 - 1300 kg

very low Energy consumption, less than 1 kW/h

Touch Panel KTP 700 and SPS S7

Technical service back-up system

New „state of the art“ design

Packaging Solutions

- manual packing machine

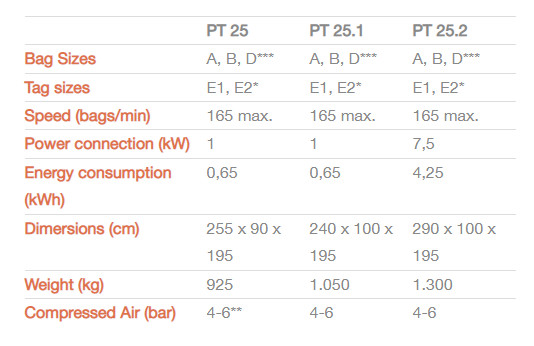

PT 25: with food grade aluminium staples

PT 125: with food grade aluminium staples to tag, with a knotting on the bag

PT 225: knotting to bag and tag

- single row cartoning device up to 25 teabags/box

PT 25.1: with food grade aluminium staples

PT 125.1: with food grade aluminium staples to tag, with a knotting on the bag

PT 225.1: knotting to bag and tag

- multirow cartoning device for boxes up to 100 teabags

PT 25.2: with food grade aluminium staples

PT 125.2: with food grade aluminium staples to tag, with a knotting on the bag

PT 225.2: knotting to bag and tag

bag size: A = 44 x 64 mm, B = 40 x 60 mm, C = 59 x 80 mm, D = 44 x 60 mm

tag size: E1 = 23 x 28 mm, E2 = 28 x 32 mm

crimped outer envelope (COE) size: bag size A,D= 62 x 70, bag size B= 58 x 67 mm

* not for bag size A ** only with knots ***only with staples

Fact sheet

State of the Art

Low machine price

Low maintenance costs

Low spare part costs

Very low Energy consumption, less than 1 kW/h

German Engineering; 100% made in Germany

Easy to operate

and more

Mechanical driven machine therefore long life cycle

Easy to maintain

Hard Tag

Knotted bags

Compact size

High Flexiblity

Technical service back-up system