Roaster Series RFB

The hot air roasters of the RFB series are the most energy-efficient roasting machines of their class and impress with their unique range of roasting profile options. Today, they are part of the standard equipment in many large roasting plants for various coffee products from specialty roasting to instant coffee production.

The RFB batch roaster is the machine with the broadest range of roasting profiles and qualities on the market. Its unique product guidance only by means of air provides many advantages:

- No moving parts in the roaster

- Unique measurement of the product temperature inside the roasting chamber

- Lowest heat capacity of the system

- Unique safety concept

- No post-roasting due to rapid cooling

The RFB thus offers an unrivalled production flexibility due to the rapid implementation of the roasting parameters and the simple recipe control. Today, it is used worldwide for a wide range of product variants and stands for batch homogeneity in terms of roasting colour and aroma like no other roasting system:

- Main stream product lines

- Slow roasting and traditional roasting aromas

- Fast roasting

- Specialty roasts

- Italian espresso variants

- Dark roasts for extraction plants

As there are no paddles in the roasting chamber and the quenching process takes place in the cooling chamber, the roasting plant convinces with minimum maintenance requirements and maximum availability for production. This increases the efficiency of your production.

The recirculation system with bypass in the roasting circuit as well as the optional green coffee preheating reduce the energy consumption and make the RFB roaster the most efficient roasting system in its class.

The RFB roasting system is available in different sizes up to 450 kg/batch and with different roasting capacities up to 4,500 kg/h.

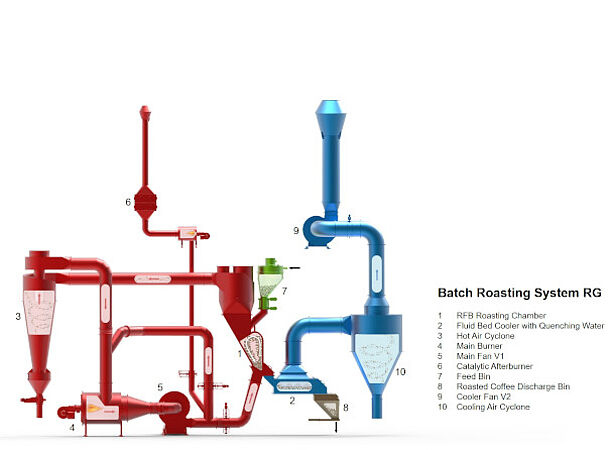

Roaster Series RG

Developed from the successful RFB series, the RG has been designed for roasting of specialties in smaller capacity ranges of up to 1,500 kg/h.

Especially for slow and espresso roasting, it offers maximum flexibility in the selection of parameters (roasting time, roasting temperature) within its range of capacities. Even small batches can be roasted precisely.

- Quality roasting for high demands

- Reproducible bean quality

- Gentle roasting without moving parts

- Convenient operation via touch panel or plant control system

- Individual aroma development which is adjusted to the respective provenance and meets the highest demands

- Gentle low-temperature roasting

- Energy-saving bypass concept

- Optionally with catalytic exhaust gas cleaning

A powerful cooling system ensures the preservation of the aromas and prevents uncontrolled post-roasting. The roasting and cooling process can be monitored continuously.

The RG roasting system is available in different sizes up to 150 kg/batch and with different roasting capacities up to 1,500 kg/h.

Roaster Series NEOROAST

The NEOROAST has been developed especially for small and medium-sized roasting plants, with its RFB chamber offering all the advantages of the larger variant. It enables the roasting master to design his roasting profiles with utmost flexibility. Traditional roasts can be produced as well as innovative flavour variations as fashion products for the new generation of coffee connoisseurs.

The product is roasted in a hot circulating air flow without any moving mechanical parts inside the RFB roasting chamber. The unique shape of the roasting chamber ensures gentle and uniform roasting of the entire batch and optimum mixing of the product. Due to the optimal energy transfer from the hot air to the bean, short-term as well as long-term roasting can be carried out in order to create an aroma profile that is ideally adapted to the coffee variety.

Furthermore, the roaster offers a higher flexibility with regard to the batch size. This allows the NEOROAST to process up to three times its smallest batch quantity.

The NEOROAST roasting system is available in different sizes of up to 33 kg/batch and roasting capacities of up to 240 kg/h.

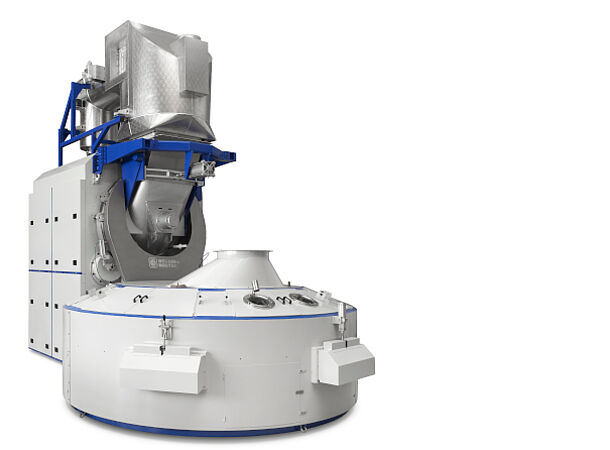

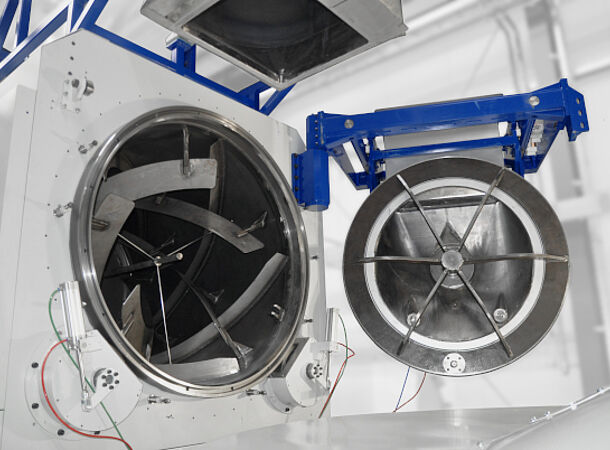

Roaster Series CTR II

The drum roasters of NEUHAUS NEOTEC provide bespoke solutions for customers who have specialised in longer roasting times and traditional roasts.

Since autumn 2020 NEUHAUS NEOTEC offers the drum roaster in the second generation. The new roasters are the consistent further development of the first generation, which set new standards in user-friendliness and service accessibility at that time. In addition, many features from the RFB hot air technology have been incorporated into the second generation, which make the new drum roaster unique in the flexibility of coffee roasting. The sophisticated heat management of the roaster allows for a greater variety of roasting curves than you know from drum roasters so far. And the CTR II also sets new standards in other disciplines such as energy management, process reliability and machine control.

- Batch size: up to 660 kg

- Closed hot air circuit with indirect heat supply

- Cold air supply for fast temperature profile changes

- KONDUX flap system for flexible change of the ratio of conductive and convective heat transfer

- Product preheating for maximum energy yield of the hot air and throughput of the roasting machine

- DARK ROAST - system for extremely dark roasts up to 35 CTN (scale COLOR TEST II)

- Optimal access to the drum through fully opening front door by means of a sophisticated swivel system

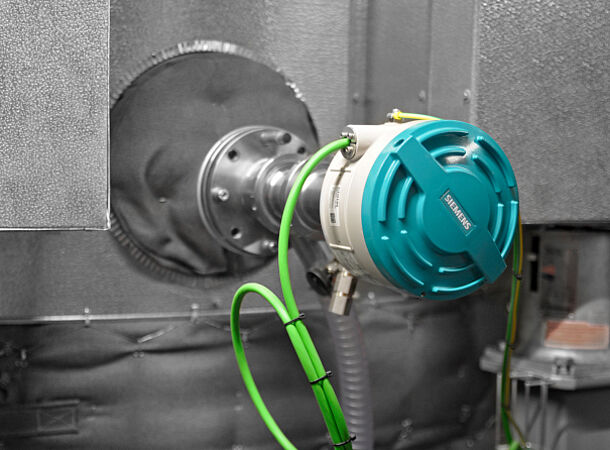

- SIEMENS control based on the TIA system architecture

- iO-Link communication for the complete sensor system

Due to the flexible combination of the roaster with different exhaust gas treatment systems adapted to the local requirements, the roaster meets the different exhaust gas regulations worldwide.

Complete Plants

Your Competent Partner in Design, Planning and Implementation

As a specialist for coffee processing, NEUHAUS NEOTEC offers complete coffee roasting plants for small, medium and large coffee roasters worldwide. We supply customized plants for the complete coffee processing chain, from green coffee intake and conditioning to roasting and grinding - all from one source. Together with our sister company DEVEX, we also offer the design and construction of complete coffee extraction plants for soluble coffee including freeze drying.

Our sales, construction and project planning teams will be at your site right from the start in order to provide you with expert advice and support in your plant design.

In the field of machine technology for coffee production, NEUHAUS NEOTEC not only develops and produces its own solutions, but also cooperates with renowned manufacturers who, with our support, optimally adapt their products to the specific requirements of the product "coffee".

NEUHAUS NEOTEC is renowned worldwide for its RFB hot air roasting process, but also offers modern drum roasting technology and helps you to select the ideal roasting process for your product.

As for ground coffee, there is a wide range of different products with just as many different requirements in terms of particle size and particle size distribution. NEUHAUS NEOTEC has developed different roll grinder series which meet the individual requirements. We will analyse the requirements on your machine together with you in our in-house pilot plant.

For product conveying and storage as part of the production process, we offer solutions that are optimally adapted to the respective production steps in order to protect the product right up to packaging and to preserve the aromas.

For the control of the coffee production plants, NEUHAUS NEOTEC develops customized IT systems that are adapted to the product requirements and which cover the complete range from signal processing within the plant to order management in the Manufacturing Execution System (MES). Intensive training of the operating personnel and simulation runs prior to the start of production ensure a smooth transition from commissioning to handover of the plant.

Worldwide Turnkey Production Lines - All from One Source

NEUHAUS NEOTEC enjoys worldwide renown as a partner thanks to the extensive portfolio and the diversity of the individual coffee roasting systems. Almost all well-known coffee roasters are among our customers, with the large roasting plants equipped with RFB hot air roasting technology ranking among the most efficient plants in their capacity class. As a matter of course, we take into account environmental aspects and strive for maximum energy efficiency.

We will be happy to provide assistance with the installation of new plants, service and maintenance of existing plants or simply in case of technical questions.