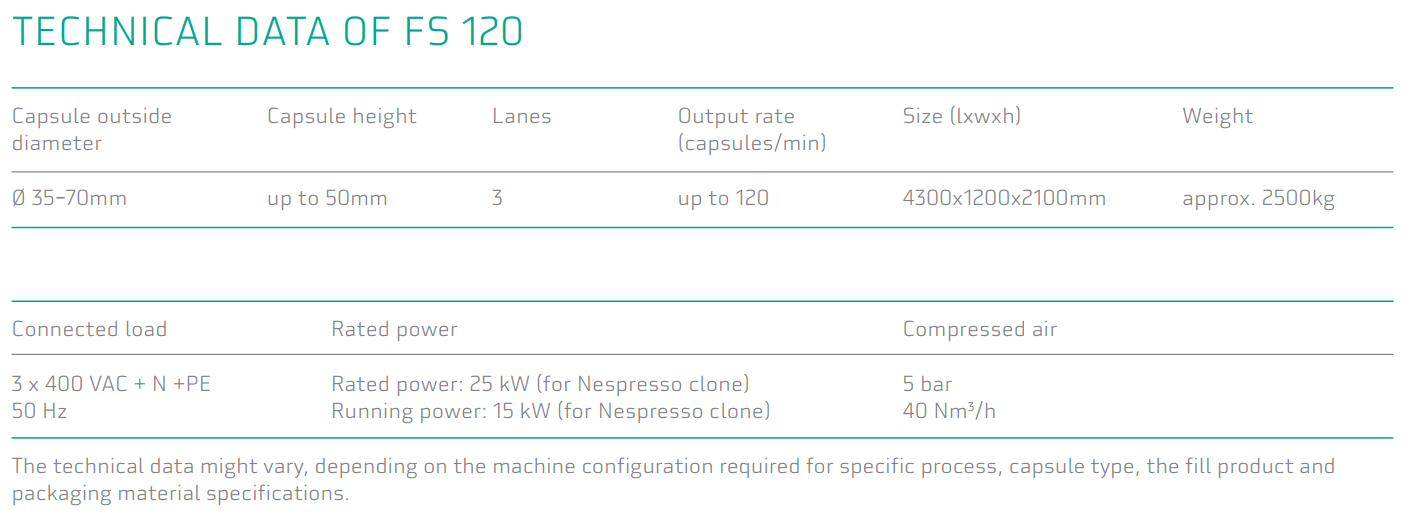

FS 120

The FS 120 is designed for customers looking for a technologically advanced small footprint filler with a throughput of 120 capsules per minute. The Rychiger FS 120 linear machine provides excellent accessibility and exceptional flexibility. Simplified cleaning and fast changeovers are only two of the many advantages of the FS 120 designed by the esteemed Rychiger design team, known for the highest quality of engineering solutions. Thanks to its modular design, the filler can be easily configured for specific processing requirements and handle capsules of various shapes and sizes, including but not limited to Nespresso®, Dolce Gusto®, and K-Cup® compatibles. A dedicated cartoning machine designed for an easy addon to the filler makes the FS 120 a unique machine in its range. It becomes a highly efficient system for processing the capsules and packaging of the completed capsules in cardboard boxes. The cartoner is designed to handle various carton sizes and formats.

Special features of FS 120

- Small footprint

- Plug & Produce concept

- Single-lane tool arrangement -> excellent accessibility

- Individually controlled, servo-driven dosing augers with optional

feedback loop for weight control - MAP enclosed smart flow section for all processes from filling to

sealing - Individually controlled and heated punching and sealing tools with

one-stroke technology - Secondary packaging unit for cartons (optional

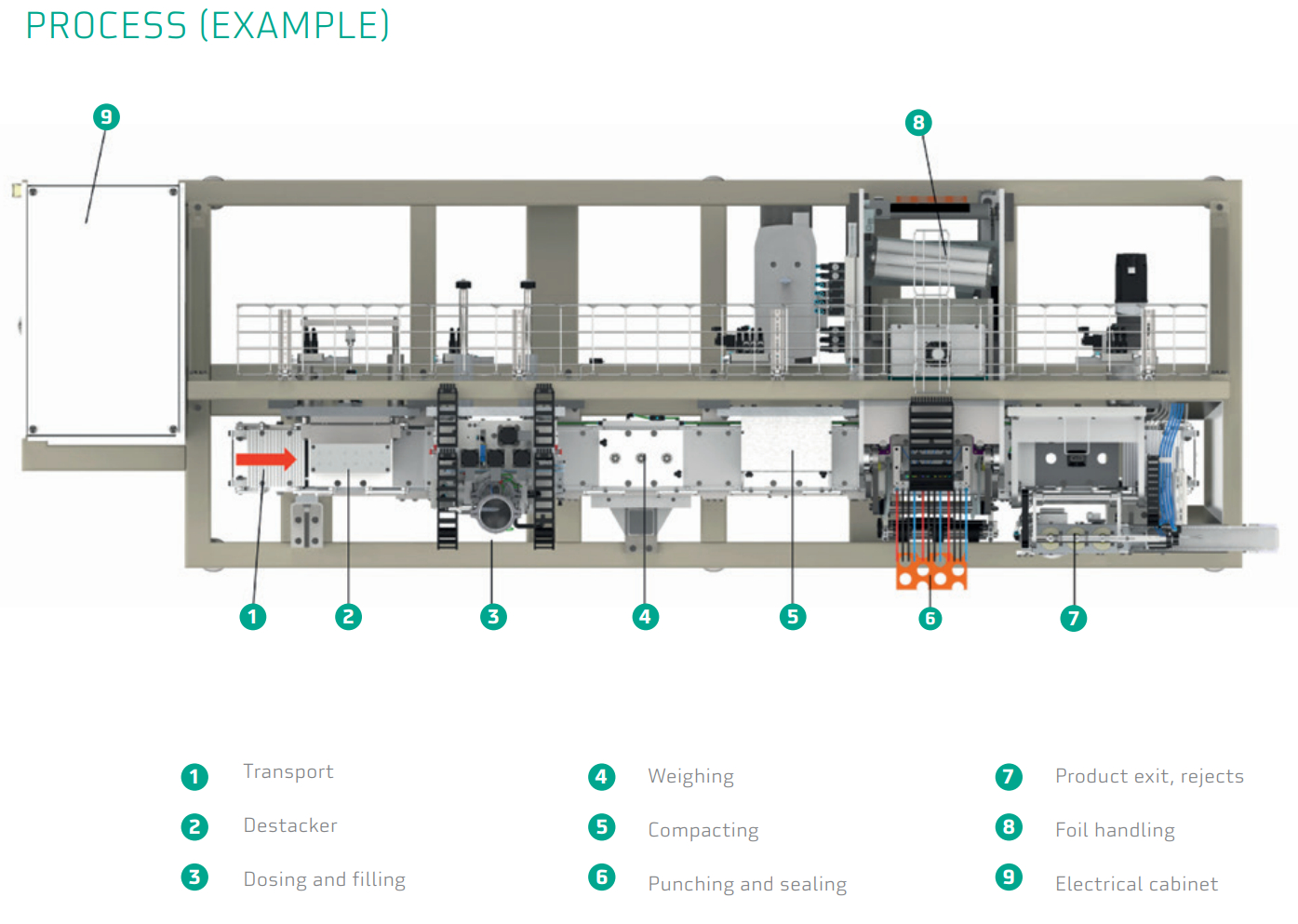

Linear transport system

- High-precision, servo-controlled linear capsule transport

- Linear arrangement of processing tools providing easy access

- Quick and easy changeovers

- Easily expandable for additional modules (option at the time of order)

Capsule infeed

- Destacker for stackable capsules

- Capsule magazine designed for easy refill

- Capsule sorting, orienting and feeding system for non-stackable, capsules supplied in bulk (optional)

Dosing and filling

- Volumetric, dosing by means of individually controlled dosing augers

- Control of individual servo-driven dosing augers by means of

downstream weighing cells - Weight control of all completed capsules on downstream load cells

- Custom-engineered auger geometry for all different applications

- Dosing of liquid flavouring agents (optional)

MAP

- Filling and sealing under protective gas in MAP tunnel

Punching and sealing

- Punching and sealing of lidding and filtering material with one-

stroke technology - Punching and sealing for roll stock material, or sealing with pre-

punched lids - Individually controlled punching and sealing tools

- Heat sealing or ultrasonic sealing (Option)

- Rugged, high-precision module with closed force flow loop

Operation and control

- Touch screen with intuitive user interface

- Plain text error messages (optional)

Optional equipment

- Bulk feeding systems

- High-precision weight measurement with feedback loop to dosing

augers - Camera systems for visual inspection

- MAP tunnel

- Secondary packaging unit

- Flavouring Module