What kind of

conveying system should you choose?

More than 40 years of reliability. Market-leading vacuum conveying systems, made in Germany. High quality and long lasting technology with low operational costs. An easy solution for non-liquid hygienic conveyors!

SIMAR FX 2004

H = 510 h = 205

D1 = 200 D2 = 240

d = 38/50

Z = 210

X = 155 Y = 154

Content = 5,0 L

at 30 m = 100 kg / h

Typical conveying capacities*

Validity:

grain size: 0,5 - 5 mm

bulkweight: 0,5 - 0,7 kg / l

* Reduced capacity for powders see our special models for powder materials

10 kg

1 KW

• filter back wash

• fault diagnosting

Compact hopper loader with single phase motor for smaller processing machines

Manufactured from stainless steel and fitted with a hinged top, these models are easy to clean and maintain.

The integrated acoustic hood of single phase conveying fan keeps noise level to a minimum.

The programmable micro-processor control unit is designed for option such as mixer valve and cleanout valve which can be easily fitted at a later date.

SIMAR FX 2504

H = 590 h = 250

D1 = 250 D2 = 250

d = 38/50

Z = 240

X = 190 Y = 179

Content = 7,5 L

at 50 m = 150 kg / h

Typical conveying capacities*

Validity:

grain size: 0,5 - 5 mm

bulkweight: 0,5 - 0,7 kg / l

* Reduced capacity for powders see our special models for powder materials

13 kg

1 KW

• filter back wash

• fault diagnosting

Compact hopper loader with single phase motor for smaller processing machines

Manufactured from stainless steel and fitted with a hinged top, these models are easy to clean and maintain.

The integrated acoustic hood of single phase conveying fan keeps noise level to a minimum.

The programmable micro-processor control unit is designed for option such as mixer valve and cleanout valve which can be easily fitted at a later date.

SIMAR FX 3500

øA = 250

øB = 290

øC = 4x ø8,5

øD = 345

E = 456

F = 468

G = 842

H = 1019

øLK = 269

• ConPuls suction impulse conveying

• Clean out valve

• Level sensor to control conveying time

• Fluidizing to support discharge

• Vibration discharging support

• Butterfly Valve DN 200/250/300

• Airlock Valve

• Larger volume of loader

• Filter for special requirements

• ATEX-version

- Mobile-Container to handle bulk materials for all industries

- Compact hopper loaders the economic way of feeding processing machines

- GraviMix: gravimeric blenders at volumetric prices

- Indoor- and Outdoor-Silos for rawmaterials

- Conveying systems for all bulk materials

- Feeding systems for packing machines

- Weigh hopper systems for batch weighing

- Discharging of Bags and Big Bags

- Dehumidifiers and Dryers

- PLC control systems

Hopper loader for dust containing materials or powders for food industries

- Stainless steel version with large filter area and filter back wash

- With 1,2 m² or 1,6 m² filter for dust containing materials like tea powders

- Conveying duct DN 38, 50, 65 or DN 80

- Vacuum pumps for different conveying capacities up to 3000 kg/hr. and more

- Programmable microprocessor control with many options

SIMAR FX 5000

øA = 350

øB = 410

øC = 4x ø8

øD = 500

E = 610

F = 1040

G = 1445

H = 1016

øLK = 390

• ConPuls suction impulse conveying

• Clean out valve

• Level sensor to control conveying time

• Fluidizing to support discharge

• Vibration discharging support

• Butterfly Valve DN 200/250/300

• Airlock Valve

• Larger volume of loader

• Filter for special requirements

• ATEX-version

- Mobile-Container to handle bulk materials for all industries

- Compact hopper loaders the economic way of feeding processing machines

- GraviMix: gravimeric blenders at volumetric prices

- Indoor- and Outdoor-Silos for rawmaterials

- Conveying systems for all bulk materials

- Feeding systems for packing machines

- Weigh hopper systems for batch weighing

- Discharging of Bags and Big Bags

- Dehumidifiers and Dryers

- PLC control systems

Hopper loader for dust containing materials or powders for food industries

- Stainless steel version with large filter area and filter back wash

- With 1,2 m² or 1,6 m² filter for dust containing materials like tea powders

- Conveying duct DN 38, 50, 65 or DN 80

- Vacuum pumps for different conveying capacities up to 3000 kg/hr. and more

- Programmable microprocessor control with many options

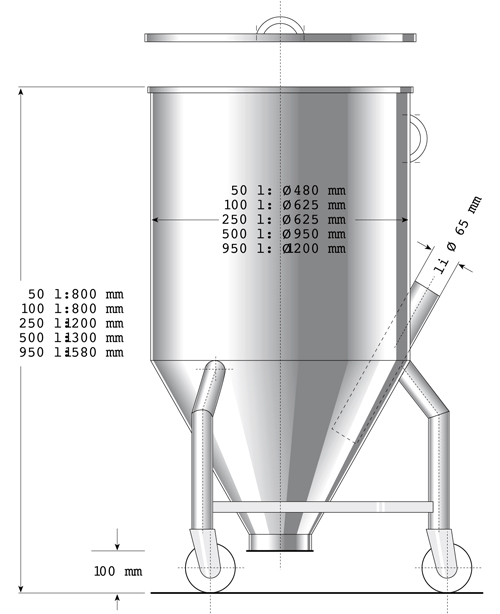

SIMAR Mobile Container

• robust aluminium or stainless steel design

• dustproof lid

• easy to move

• 5 standard sizes

• Emptying slide

• Push in point for suction pipe

• Easy to move casters with brake

Optimize your material storage by using the range of mobile containers!

Simar supplies systems for conveying, storaging, dosing, weighing and drying of bulk materials!

Mobile container to handle bulk materials like tea

- Aluminium or stainless steel design

- Easy to remove

- Push in point for suction pipe

- Easy to clean

- Volumen: 50, 100, 250, 500, 950 Liter