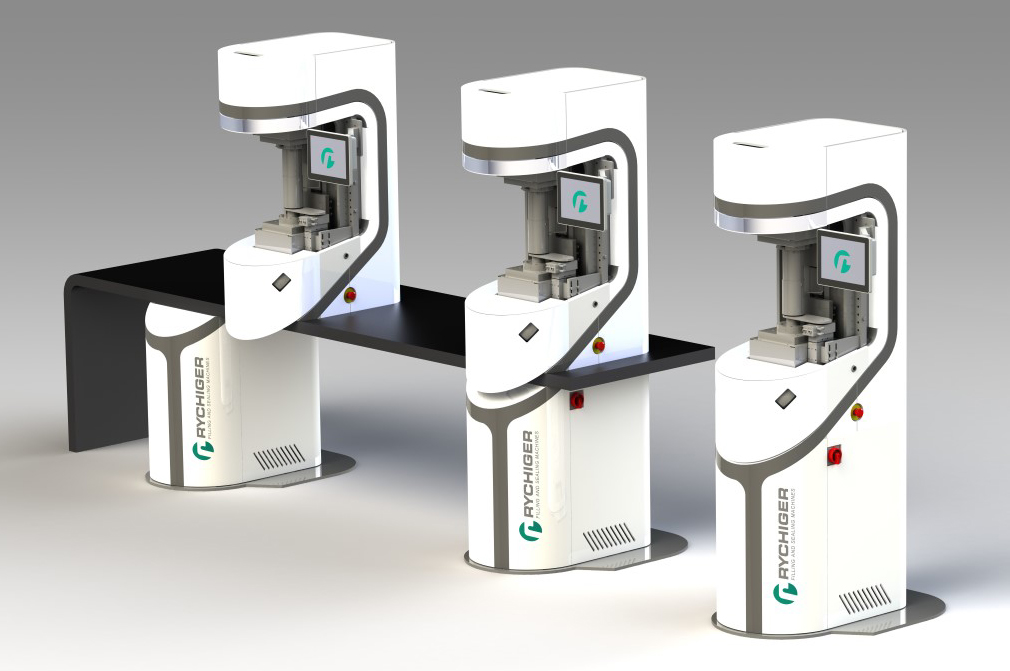

RD 06

Perfect sealing for small series

With the RD 06, you can test all your processes in connection with punching and sealing – even under clean room conditions. Subsequently, these processes can be scaled up with precision to industrial production levels.

- Feasibility studies

- Production testing

- Small-series production

- Approved for clean room applications

- Format parts testing

The RD 06 is designed to seal a wide range of packaging types and products, covering basically everything you could possibly want to manufacture in the food&beverage or healthcare sectors. The processes are highly adaptable and run in semi-automated mode. Process parameters can be entered through the HMI, and subsequently reproduced for industrial production.

The RD 06 is extremely compact and fits into any lab. It has been designed for operation in ISO class 7 and 8 clean rooms and is the ideal solution for production test runs and small-series production.

The RD 06 produces perfect seals and caters to sealing and punching in a single process, using Rychiger's one stroke technology known from its larger machines. The machine can be extended with a foil handling unit for foil feed from rolls, or a separate trolley for liquid filling.

Where certain tasks need to be performed by hand, operator safety and good ergonomics are particularly important. That is why the RD 06 is designed for control through an intuitive touch panel. For extra safety, a punching and sealing cycle can only be started with a two-hand control.

By investing in an RD 06, you buy advanced technology at a competitive price. If you wish to produce a very small number of samples of your new product for presentation to investors, you can lease an RD 06 from us.

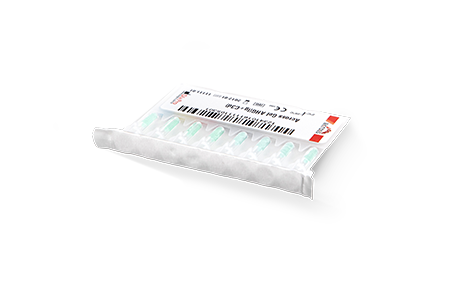

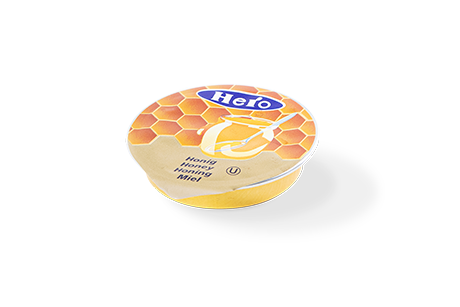

Can be produced on the RD 06